The clips and fasteners therefore are concealed underneath the metal panels when properly installed arguably making the roof more aesthetically pleasing.

Metal roof with visible fasteners.

Too often it is caused by under or over tightening of roof fasteners that causes the metal to stretch pull and dimple in various directions.

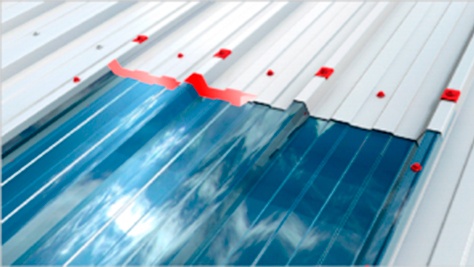

The edges of the panels overlap and fasteners are screwed through both layers.

Concealed fasteners are unable to be seen after installation is complete.

Turn your sights to stealthbond the first adhesive based metal roof installation system that eliminates the need for exposed fasteners.

Metal roofs have two main connection strategies to the building below either concealed or exposed fastener systems.

The fasteners are secured beneath the metal panels making for a smooth uninterrupted surface.

The two most common ways of attaching a metal roof to a structure are exposed fasteners and concealed fasteners.

The hardware is visible on the outside of the roof here post installation.

Exposed fastened metal roof.

On an average the lifetime of such a metal roof is 20 30 years.

An exposed fastener system is typically considered the economical choice of metal roofing and is classically used on residential structural industrial and agricultural buildings.

It s called exposed fastener because the head of the fastener is visible and not hidden by a seam.

This kind of fasteners makes the head of the fastener rust proof and thus the washer becomes virtually a lifetime product.

Another solution is you can opt for a fastener with a non metallic head fully covering the neoprene washer available at metal buildings colorado.

Exposed fastener roofs are less expensive than standing seam systems.

But as a rule of thumb if the washer is splayed out and visible then the fastener is too tight.

The benefits of exposed fastener ef cost.

Exposed fasteners involve driving a fastener through the panel and right into the deck of the roof itself.

Exposed fastened metal roofs aren t exactly in vogue these days but they do represent a tremendous value in the right situation.

The fasteners remain visible.

The panels overlap and the fasteners are drilled into both layers leaving them visible to the naked.

Although concealed fasteners are more expensive than exposed types they offer several advantages for a long lasting metal roof.

Because concealed fasteners are hidden below the metal roof sheeting they are not subjected to pounding weather patterns.

Concealed fastened panels are attached to the substrate with clips which means the panels are not pierced to secure the connection.

Here is an example of an exposed fastener system using bridger steel s 7 8 corrugated panels.

When a metal roof fails.

Luckily with the advancements in adhesive technology you can now have a metal roofing system without exposed fasteners.